- Guaranteed Secure Payments on Every Order

- Refund if your item is not delivered or as described

- Buyer Protection after order confirmation

- Place of Origin: qingdao

- Brand Name: shengtong

- Model Number: STSK-SF30

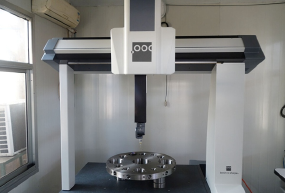

Controlled press equipment introduction:

The numerical control punching machine is configured with a multi station turret die, which can automatically and quickly replace the mold, and is suitable for processing various kinds of panel punching and shallow drawing process, and the production efficiency is greatly improved.

1 configuration 12 work station turret mold, with A, B, C, D station, automatic change.

2 LCD control system using industrial integration workstation, using the touch panel, flexible and convenient operation; the software according to the requirements of users can add functionality, lifelong customers free upgrade, can realize the automatic conversion of AutoCAD graphics processing procedures, with mould database management, realize automatic plate positioning, can be a key operation, processing, display and simulation breakpoint piece display processing track, equipment idle operation diagnosis etc..

3 machine tools: 300KN, 500KN, 700KN impact.

4 stroke machine: 280 times / min.

5 lead screw, guide rail, motor and the main electrical components are imported brands, to ensure the overall stability of the equipment.

6 the total float pneumatic clamp and high elastic brush working table, the material will not be scratched.

7 equipped with centralized lubrication system, to achieve the lead screw, guide rail and other major drive components can achieve centralized lubrication, extend the life of the equipment.

8 automatic discharge and waste collection device.

9 machining range: 2500mm*1250mm

Numerical control punch technology agreement:

Our company solemn promise: the transmission part of the equipment and the main parts are all imported

In the same kind of products, we can realize the processing without blind area.

Impulse pressure: 300KN;

Effective stroke: a positioning 2500mm * 1250mm;

Chong times: 180 times /min - 280 times /min;

Max. sheet thickness: T = 6mm;

Stamping bed: the pneumatic friction clutch brake, safe double valve control; high rigidity of O- type frame structure, the carriage and the beam integration design, enhanced rigidity, more accurate positioning, high speed feeding is more stable, eliminate the worktable of X, Y axis dynamic offset;

Turret mold: using the world's most advanced thin turret, long guide Amada mold, reduce the weight of the mold disc while still maintaining a long guide structure, positioning accuracy

Cylinder: South Korea ARK import cylinder, precise locking and positioning;

Lead screw: South Korea imported large lead precision ball screw;

Guide rail: Taiwan wide straight guide rail, the use of widened flange type slider;

Motor / Driver: Taiwan AC servo motor, stable and reliable performance;

Main electrical components: switching power supply, relays, sensors, contacts, and other imported parts;

Control unit: integrated LCD display, strong function, to ensure the stability of the program, software and the overall equipment; separate control cabinet and bed separation;

Coupling: Taiwan Jian Xiang flexible shaft coupling to ensure that the transmission and correction accuracy;

Reducer: Taiwan Thomas (TMOX) brand machine, high precision to ensure the accuracy of the positioning of the cylinder;

Clamp: using float pneumatic clamp, together with the floating plate, clamping force and convenient feeding, avoid plate distortion;

Working table: high quality elastic brush and ball worktable, smooth operation, no resistance, no scratch plate; automatic graphic conversion processing program; with mold library management system; automatic plate positioning; can achieve one button operation, breakpoint processing, display and simulation map display piece processing path and other functions;

Control axis number: 3 axes (X, Y, T);

Lubrication system: the machine is fully automatic cycle lubrication, which greatly reduced due to improper lubrication caused by equipment failure

- Place of Origin: qingdao

- Brand Name: shengtong

- Model Number: STSK-SF30